For Pharmaceutical/Clean Steam applications, the SQ1-T Sanitary Steam Quality Test Kits provides compliance with European Regulatory Standards EN 285 and HTM 01-01 (replaces HTM 2010), International Standard ISO 17665, and USA Guidance PDA (Parenteral Drug Association) Technical Report No. 1.

The SQ1-T Test Kit provides the ability to perform the following tests:

- Non-Condensable Gas (NCG) Test

- Dryness Test

- Superheat Test

The SQ1-T Test Kit has been designed to comply with EN 285 with a single improvement to the methodology. It should be noted at the outset that EN 285 specifically allows alternative procedures, provided that they have been calibrated against the standard methods.

Instead of the non-condensable gas test being as described in the standard, we provide a condenser system which we have found to be safer, more robust, easier to use (less subjective), and more repeatable. The objective is to separate non-condensable gases from steam and the disadvantage of the standard method is the subjective adjustment of steam flow to prevent localized boiling and therefore the collection of non-condensable gases from the water being used to condense the steam. By using a condenser, the steam does not come into contact with the water and eliminates this subjective and variable aspect.

Condensers tend to be the preferred method for test professionals, though the disadvantage is usually the need to modify pipework in the plant room to have access to a cold water supply. With our system we provide a small submersible water pump, which can simply be dropped into the sterilizer header tank or a bucket of cold water.

The test kit was designed by field engineers, primarily for their own use and has been comprehensively field-tested. A detailed manual is provided, giving details of the test points required, test procedures and an Excel calculation for establishing dryness values etc. It should be noted that the dryness value measurement is not restricted to a minimum value as will be found with some test kits.

Regulatory Approval

As far as we understand, our equipment has not been the subject of European regulatory scrutiny, though the results generated by it has, without comment on the equipment or indeed methodology. The approach of the regulators would seem to be: –

- Are the consequences of poor steam quality understood?

- Have tests been conducted, and what are the results?

- If out of specification, what action is being taken?

Accuracy – Dryness Value & Superheat

The equipment supplied complies exactly with EN 285. These tests are approximations and inferential respectively. The tests are conducted in accordance with EN 285 or HTM 01-01 and the results used accordingly. It is therefore not possible to benchmark these tests with any standard.

Accuracy – Non Condensable Gas test

For non-condensable gas testing we state that our equipment complies with EN 285 as this standard specifically allows the use of alternative methods provided they have been shown to give comparable results. This comparison work has been undertaken and the results showed that the difference between the EN 285 method and our system for non-condensable gas tests was 0.03% over five tests with values between 0.4 and 1.6%.

While the results provide some value, you should remember in the case of the non-condensable gas test that we have a system capable of producing consistent results which we have to compare with a subjective test method!

The method we use is essentially the same as that used to train Test Persons at Falfield, the main center for training UK National Health Service Engineers and where the MHRA has received training.

The test objective is very simple, steam must be condensed and any gases resulting collected. Our system performs this function consistently and repeatability from test to test, irrespective of the skills of the person carrying out the test.

SQ1-T Steam Quality Testing Accessories

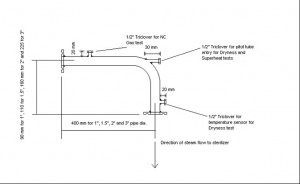

Test Elbows

We offer Steam Quality Test Elbows (Tri-Clover process connection / Tri-Clover Sample Ports). These Test Elbows provide a fast and easy way to perform all the steam quality tests. Available in 3/4″ to 6″ diameter and finished to 15 Ra EP I.D / 32 Ra O.D, our Test Elbows are meant to remain in place when not testing, and are provided with a complete validation documentation package (MTR’s, Weld Map and Log, Surface Finish Certificate, and Citric Passivation Certificate). We can also provide additional documentation (ie Level II Inspection) at an added cost. Please contact us for pricing.

Electronic Balances

An electronic balance (0 – 3000g/accuracy 0.1g) is required for the dryness test, in addition to the test kit supplied. While most facilities have these available, the presence of a balance to be used exclusively with the SQ1-T Test Kit increases productivity.

We supply a lightweight, rechargeable battery/mains, rugged precision compact balance specifically for this application.

Handheld Temperature Meter/Logger and Probes

While any data logger may be used for the steam quality testing, we can also supply a dual input hand-held temperature meter/logger with two Type T Thermocouples, as two temperature inputs are required for the superheat and dryness value tests. The thermometer offers a fast response and laboratory accuracy (+/- 0.05% + 0.3°C) in a rugged hand held test tool. Has logging facility with Max/Min/Average calculations and PC connectivity, which makes it ideal for this application. Complete with NIST Calibration Certificate (Logger only)

Thermowell Temperature Probe

For a semi-permanent solution for monitoring the steam pipe temperature during testing, we offer a Tri-Clover Thermowell fitted with a Type T Thermocouple that is fitted on the temperature sample port of the Test Elbow.